With extra People than figuring out as makers, we’re seeing new merchandise arrive to scratch that itch daily. Machines like 3D printers, vinyl cutters and laser cutters at the moment are obtainable at costs to suit nearly any pocketbook. They permit individuals to carry their creations to life in new and fascinating methods. You’ll be able to even flip a revenue on shops like Etsy and Shopify when you’ve got the best supplies and machines.

I’ve used laser cutters for about 5 years to create varied tasks, from small canine tags to etching a 7-foot workbench with elven runes. Every cutter I take advantage of has a bunch of various professionals and cons, so together with my CNET colleague Russell Holly, I’ve developed testing standards to evaluate one of the best laser cutters.

Chances are you’ll discover that there aren’t any open laser cutters on this record. After testing a number of I discover them to be too harmful for the common consumer. They could possibly be good for business areas, however having an open laser in a storage is simply too harmful for me to suggest.

What’s one of the best laser cutter?

The xTool P2 is our high choose for one of the best laser cutter. It is not the most cost effective laser cutter round, however with a bunch of wonderful equipment, improbable software program and a reducing dimension and velocity which can be laborious to disregard, it takes the crown from the Glowforge Professional, however simply barely. It is big, so be sure to have room in your workshop to accommodate it.

Greatest laser cutters of 2024

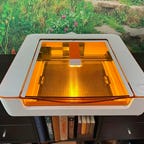

The xTool P2 is the whole package deal for quick, highly effective laser reducing at house or in a small workshop. With a full suite of equipment that allow you to reduce 3-meter-long supplies and spherical tumblers and glasses, the P2 can reduce or etch any materials you may hope for, together with glass and clear acrylic.

The software program is superb and may help you design your creations to higher suit your reducing wants. The digital camera works nicely that will help you align your supplies, however watch out when working close to the sting of the digital camera limits, as a result of the fisheye distorts a bit. This bundle comes with some supplies to get you began and a hearth security system to offer you peace of thoughts.

The Glowforge Aura is the corporate’s first client laser cutter aimed on the entry-level market. It is smaller than the opposite fashions, with a much less highly effective laser, nevertheless it works amazingly nicely on smaller tasks. We have made stunning carvings, etchings and different laser-cut tasks on the aura, and all of them have been glorious.

Learn extra: Arms-on with the Glowforge Aura

It has been some time since I’ve had as a lot enjoyable with a maker software as I’ve had with the xTool F1. It is light-weight and really straightforward to move in the event you go to many commerce exhibits, conferences or farmer’s markets and, with the equipment on this bundle, you possibly can etch batches of merchandise as simply as one. The software program is superb too, making it straightforward to line up tasks or hint out new tasks from a photograph.

I not too long ago took the F1 to a STEM honest for major college children, and it was extraordinarily well-liked because it whizzed round reducing out the college brand onto metallic enterprise playing cards. Whereas the worth is fairly excessive for a reducing space this small, you may simply make your a refund with just a bit work at a farmer’s market stall or two. It is nicely well worth the funding.

The Beamo is the smallest of Flux’s spectacular lineup of CO2 laser cutters, however do not let the small dimension idiot you. The 30-watt laser, whereas weaker than some on this record, remains to be highly effective sufficient to etch glass, though chances are you’ll want the extra diode laser to etch onto the metal. It is going to fortunately reduce by way of wooden, leather-based and acrylic.

The Beamo additionally comes with a useful touchscreen on the machine, making it a lot simpler to manage out of your workshop with out a pc plugged into it immediately. Flux even has an app that’ll allow you to management the Beamo immediately out of your cellphone.

The WeCreat is a enjoyable little field that may etch and reduce a number of supplies. It is not going to carve by way of thick wooden or metal, nevertheless it makes enjoyable tasks for household enjoyable time. I believe it is excellent for faculties, particularly with its exhaust filter, because the enclosure and air help make it secure for school rooms and cease little fingers from getting burnt. I created a number of tasks for my child’s kindergarten class, and the academics all beloved it.

Whereas the software program is not fairly pretty much as good as Xtool or Glowforge, the digital camera is correct and allows you to mark the place your materials is nicely. It even has testing squares, so you possibly can check out any materials and see what energy degree you want. That is one thing all laser cutters ought to have.

Diode lasers are sometimes low-powered, with no enclosure to maintain you secure. The S1 solves each these issues by having a 40-watt laser that may reduce by way of 18mm of wooden in a single, albeit sluggish, move. It additionally has a improbable enclosure with a inexperienced lid to filter the laser’s gentle and an energetic exhaust to blow away any smoke. The essential equipment has air help — one thing all lasers ought to have — and a honeycomb reducing floor to assist cut back scorching on the underside of your materials.

The S1 would not have a digital camera — I believe it ought to — so every thing is dealt with very manually. However that is true for many diode lasers.

Glowforge has made it clear its mission from the beginning has been to make sure anybody can use what it calls “laser printers,” and the Glowforge Professional is a shining instance. A fisheye digital camera offers you a view of the reducing floor from an online app, which helps you to effortlessly click on and drag the stuff you wish to engrave or reduce. And in the event you pay for the additional filtration system, you need to use this laser wherever. Of all of the techniques examined right here, Glowforge’s deal with ease of use is a world aside.

With that ease of use comes some limitations you will not discover elsewhere. Many options that make the Glowforge Professional nice can be found provided that you pay a month-to-month subscription. In the event you’re not utilizing the Glowforge-made Proofgrade, the method of figuring out the proper settings for engraving or reducing turns into fairly guide. Moreover, the fisheye lens that Glowforge makes use of can often trigger accuracy points whenever you’re reducing or engraving on small, completely centered surfaces.

You’ve got bought questions and we have solutions. We hope!

Testing laser cutters is a mixture of goal and subjective measures. We spend time measuring velocity and accuracy in addition to usability and the general look of the completed product. These exams are completed in our labs and workshops over a month to make sure the lasers can endure correct use.

Laser cutter specs

How do these laser cutters match up

| Xtool P2 | Glowforge Aura | Xtool S1 | Fluxx Beamo | Glowforge Professional | XTool F1 | |

| Laser energy | 55 watts | 6w | 40w | 40w | 45W | 10W |

| Laser sort | CO² | Diode | Diode | CO2 | CO2 | Diode/IR |

| Work space | 26 x 14 inches | 12 x 12 inches | 498 x 319mm | 24 x 17.5 inches | 660 x 355 | 115 x 115 |

| LED show | No | No | No | Sure | NO | No |

| Enclosed | Sure | Sure | Sure | Sure | Sure | Partial |

| Precision | 0.01mm | N/A | 0.01mm | N/A | 0.025 | 0.02 |

| Max velocity | 600mm/s | Unknown | 600mm/s | 300mm/s | Unknown | 4000mm/s |

| Max materials thickness | 20mm | 5mm | 18mm | 5mm | 13mm | 5mm |

Velocity is examined with a superb old style stopwatch. I created a easy CNET brand design that may be reduce on a number of supplies. We time how lengthy it takes to finish the reduce. We use 3mm basswood, 3mm black acrylic and three.5mm cardboard for our testing supplies, to offer us a superb general view. We then evaluate the velocity with the software program to see how precisely it calculates the reducing speeds.

The engraving is completed with a picture of my stunning canine Indiana Bones. I imported that picture into the workspace and used 3mm basswood for the fabric. I take advantage of the usual engraving settings from every machine to engrave Indy onto the wooden. My CNET colleague Russell Holly and I then look at the etching for picture high quality. We’re taking a look at distinction, the extent of element captured, and the way grainy the picture is, in addition to contemplating our opinion on the general high quality.

Indiana is the proper check topic for laser engraving.

For laser cutters with cameras, I created an accuracy check. I designed a file with 10mm and 5mm increments. The file is printed on normal paper and imported into the laser cutter software program. From there, we use the laser cutter digital camera to align the bodily marks to the digital and set the laser to chop. As soon as the laser is completed, we measure the offset utilizing a micrometer to see how precisely the digital camera represents the paper picture. That is particularly useful for laser cutters with fisheye lenses.